Wireless Private Network Solution for Shipyard Intelligent Control System

China’s shipbuilding industry has maintained an unshakable leading position in the global market for 15 consecutive years, with its comprehensive strength reflected in multiple dimensions such as market share, technological breakthroughs, production capacity efficiency, and industrial chain collaboration.

According to 2024 data, among the 18 mainstream ship types worldwide, China ranked first in new orders for 14 types (including car carriers and multi-purpose ships), while only 4 types such as LNG carriers and LPG carriers have not yet reached the top. The completed new ship volume accounted for 55.7% of the global total (48.18 million deadweight tons), a year-on-year increase of 13.8%; the new orders received accounted for 74.1% of the global total (113.05 million deadweight tons), a year-on-year increase of 58.8%, hitting a record high; the backlog of orders accounted for 63.1% of the global total (208.72 million deadweight tons), a year-on-year increase of 49.7%, which can meet the workload for nearly 4 years in the future; the new orders received were more than 3 times that of South Korea, with container ship and bulk carrier orders accounting for 90% and 81% of the global total respectively.

China’s shipbuilding industry drives its global leadership with the “troika” of “scale, efficiency, and green innovation”, but it needs to achieve a leap from “quantity” to “quality” through technological independence and high-end industrial chain development. If it can make breakthroughs in the field of LNG/LPG carriers and cope with international policy encirclement in the future, it will further consolidate its position as a “strong shipbuilding country” and support the in-depth development of the marine economy strategy.

The reason why China’s shipbuilding industry has been able to lead the world for a long time is not only due to its advantages in cost, industrial chain, talent, and technological breakthroughs, but also inseparable from the “four modernizations” upgrading of shipyards in terms of automation, intelligence, digitalization, and unmanned intelligent control. “Intelligent control” has enabled traditional shipbuilding to move towards modern shipbuilding with low cost, high efficiency, and high safety. The cornerstone of intelligent control in shipyards is networking. Without a reliable, secure, and stable network, intelligent control would be nothing but an illusion. Wired networks represented by optical fiber networks mainly meet the networking needs of fixed information points, while mobile scenarios mainly rely on wireless private networks. This article aims to provide guidance for shipyard users on the construction of wireless private networks, helping shipyards build safe and reliable wireless private networks.

I. Special Challenges Faced by Wireless Communication in Shipyards

As a typical heavy industry manufacturing environment, modern shipyards are characterized by vast coverage areas, dense metal structures, and complex electromagnetic environments, posing extremely stringent requirements for wireless communication systems. In a typical shipbuilding operation scenario, the entire process—from steel plate cutting, segment prefabrication, large gantry crane transportation to dock assembly—involves the coordinated operation of dozens or even hundreds of lifting equipment, real-time monitoring of tens of thousands of sensors, and precise scheduling of cross-regional operators. However, traditional WiFi or 4G public networks face multiple dilemmas in shipyard environments:

- Signal shielding issues: Complex metal structures formed by enclosed hull compartments, steel plate yards, and large-scale equipment exert a strong shielding effect on wireless signals, reducing the transmission distance and coverage effect of conventional wireless devices.

- Insufficient mobility support: When heavy equipment such as gantry cranes moves at a speed of 2-5 m/s, the handover mechanism of 4G/5G public network base stations struggles to ensure the continuity and real-time performance of control signals.

- Data security risks: The transmission of production data through 4G/5G public networks carries the hidden danger of information leakage, which fails to meet the confidentiality requirements for military industry and high-value ship manufacturing. For details on the security issues of 4G/5G public networks, please refer to the article *In the 5G Era: Network Security and Physically Isolated Private Networks in Network Construction for Government and Enterprise Customers*.

- Bandwidth bottlenecks: Digital twin systems need to simultaneously transmit multiple 4K video streams, 3D laser scanning point clouds, and equipment status data. The total bandwidth demand often reaches Gbps, far exceeding the carrying capacity of ordinary networks.

- Convergence of multiple networks: Each intelligent control system has its own independent networking part. On one hand, repeated investment leads to waste; on the other hand, severe wireless interference affects each other. There is an urgent need for a supplier to provide unified planning and design, enabling multiple services to share the same network platform. At the same time, the reliability of this platform should be enhanced to ensure the availability of multi-network convergence.

In response to these challenges, GuoXin Longxin has built an industry-leading customized wireless private network solution for shipyards based on four core technology systems: iMAX wireless metropolitan area network system, FibeAir millimeter-wave wireless private network, iMAX waveguide or leaky wave cable, and BreezeAir WiFi6 & WiFi7. This solution has been successfully applied in many large shipyards and marine engineering equipment manufacturing bases for many years.

II. Core Technical Advantages of GuoXin Longxin Wireless Private Network

GuoXin Longxin’s iMAX Wireless Metropolitan Area Network (WMAN) system adopts 5GHz wide frequency, featuring high bandwidth, ultra-long communication distance, and high performance; the FibeAir millimeter-wave system offers higher bandwidth capacity, making it ideal for achieving breakthrough transmission performance in the complex environment of shipyards; the iMAX waveguide system significantly enhances the anti-interference capability of the wireless system, reduces network packet loss rate, delay, and jitter, ensures high system performance, and fully meets the stringent networking requirements for crane remote control; the iMAX leaky wave cable system improves wireless anti-interference capability, enabling the deployment of reliable and stable wireless systems in some special metal-enclosed environments; BreezeAir WiFi6 & WiFi7 easily realizes the construction of high-bandwidth links of several Gbps at low cost and the networking of WiFi intelligent terminals.

The following will take iMAX Wireless Metropolitan Area Network (WMAN) private network technology, iMAX waveguide/leaky wave cable, or FibeAir millimeter-wave as examples to explain several advantages of GuoXin Longxin’s wireless private network technology.

2.1 Advantages of iMAX Wireless Metropolitan Area Network Technology

- Three high characteristics: Supporting high bandwidth (1.2Gbps peak air interface rate), high capacity (single base station accessing 500+ terminals), and high stability (99.99% availability). A single base station can meet the requirement of simultaneous backhaul of 50 channels of high-definition videos.

- Three low characteristics: Low latency (wireless transmission latency ≤ 3ms), low failure rate (Mean Time Between Failures (MTBF) of more than 200,000 hours), and low cost (compared with the operator’s 5G private network networking mode in shipyard scenarios, the cost is only 1/n, and it is a one-time investment with no subsequent traffic fees or management fees).

- High reliability mechanism: Based on OFDM/TDMA dynamic modulation technology, coupled with high-reliability technologies such as RSTP, multi-link data mirroring, and VRRP virtual hot standby routing protocol, plus the adaptive adjustment capability to automatically downgrade to ensure link smoothness in severe weather such as rain and fog, the network stability and reliability can be easily improved to over 90%.

- High network security characteristics: The iMAX system supports wireless SSID grouping, provides a MAC address control list (MCL), dynamic encryption of data transmission (AES), and a built-in firewall, meeting high-level private network security requirements.

2.2 Anti-Interference Reliability in Complex Environments

In response to the unique strong electromagnetic interference from electric welding, start-stop impact of large motors, and metal reflection multipath effect in shipyards, GuoXin Longxin has developed a multi-dimensional anti-interference system:

- Multi-spectrum sensing: Through the built-in spectrum scanning and analysis tool of the system, spectrum monitoring on the shipyard site can be easily realized, dynamically avoiding 2.4GHz/5.8GHz industrial interference frequency bands and other wireless interferences.

- Anti-interference mode: For interference and mobile scenarios, the iMAX system is equipped with advanced anti-interference technologies. By reducing bandwidth, increasing retransmissions, and other methods, it improves the system’s anti-interference capability and optimizes network transmission effects.

- Application of multi-link data mirroring or multi-link aggregation technology: Key control commands are transmitted synchronously through multiple independent physical links, using Forward Error Correction (FEC) and space-time diversity algorithms. Even if a single link is interrupted, communication can still be guaranteed.

- Application of waveguide system: Based on the iMAX system’s excellent anti-interference, mobile roaming, and three-layer routing technologies, combined with the specially developed and customized 5GHz wide-frequency waveguide technology, the anti-interference capability of the wireless system is greatly enhanced. This enables the network to achieve high bandwidth, high capacity, and low latency even in environments with strong electromagnetic interference, thus meeting the usage requirements of scenarios such as intelligent control of large cranes or unmanned driving.

- Application of leaky wave cable system: Based on the iMAX system’s excellent anti-interference, mobile roaming, and three-layer routing technologies, combined with the specially customized medium and high-frequency leaky wave cable technology, the anti-interference capability of the wireless system is improved. It ensures the deployment of wireless anti-interference in low-bandwidth scenarios such as robots, AGVs, and assembly lines, and can also meet the wireless network coverage requirements for operations in enclosed shipyard scenarios (such as the interior of metal ship cabins).

2.3 Intelligent Roaming and Multi-Mode Redundant Architecture

In response to the continuous communication needs of mobile devices, GuoXin Longxin has developed roaming and network redundancy architectures such as VRRP virtual hot standby routing technology and multi-link data mirroring, which can meet roaming and redundancy requirements:

- Millisecond-level seamless roaming: When a gantry crane moves at a speed of 5m/s, the base station handover time is <10ms, and the packet loss rate is <0.001%, ensuring the continuity of real-time modeling in the digital twin system. Especially when combined with waveguide or leaky wave cable technology, it can better meet the roaming and handover needs of machines, vehicles, and personnel in mobile roaming scenarios in shipyards.

- Intelligent switching between private network and public network: If the shipyard requires 4G/5G network access, such as in ship launching test scenarios, the iMAX-4GW300 dual-mode gateway realizes seamless switching between the local private network and 4G/5G public network. It prioritizes the use of high-bandwidth private networks within the factory coverage area and automatically switches to the operator’s virtual private network when transferring to external cooperation wharves, significantly reducing monthly traffic costs.

III. Implementation of Core Application Scenarios for Shipyard Intelligent Control Systems

3.1. Lifting (Dual-Machine Coordination) Networking System

Shipyards often have operational requirements for dual-machine lifting with large shipbuilding cranes, which are extremely demanding:

- Precision requirements: Dual-machine lifting must maintain a hook level error ≤ 5cm to avoid tilting of heavy objects (such as thousand-ton级 hull sections).

- Real-time coordination: The synchronization delay of dual-machine actions must be < 20ms to prevent steel cable tension imbalance.

- Environmental interference: GPS/Beidou signals are shielded by the shipyard’s metal structures, resulting in a high interruption rate of conventional wireless communication.

- Safety redundancy: Emergency mechanisms must be activated within 50ms in case of a single point of failure.

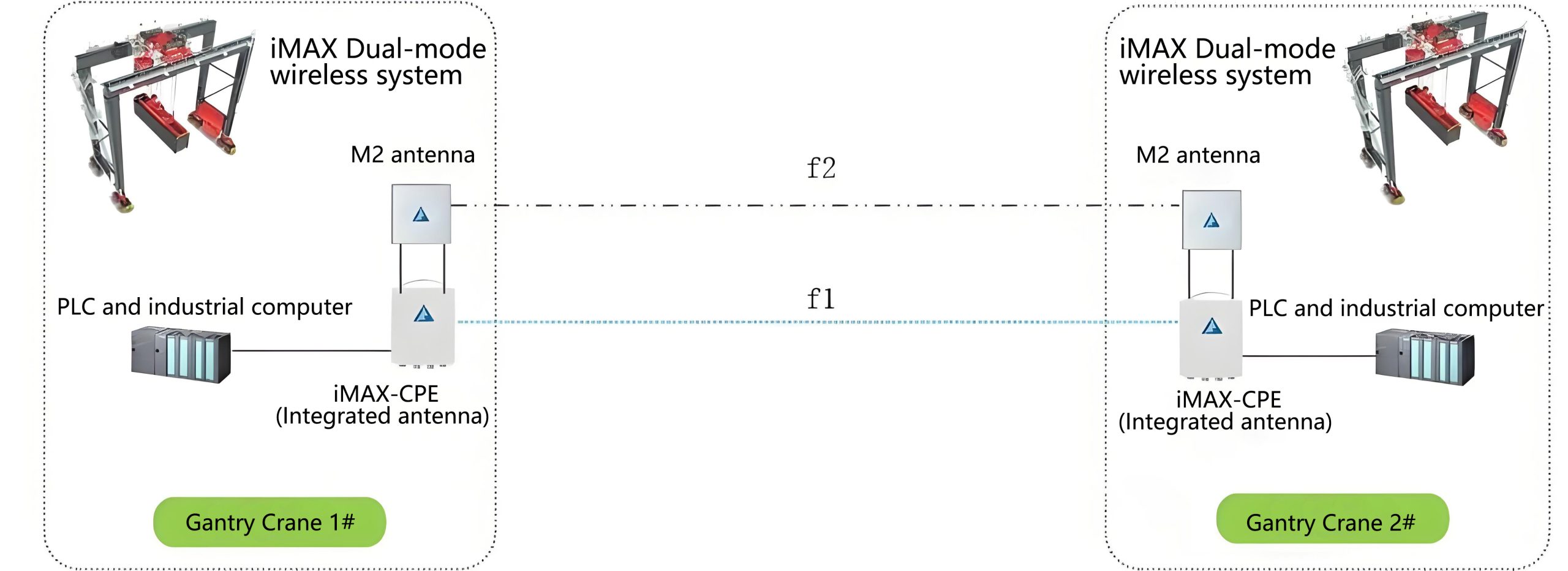

The corresponding network system must also have low latency and multi-layer redundancy characteristics to ensure its reliability, safety, and stability. The GuoXin Longxin wireless private network system applied in lifting scenarios breaks the limitation that traditional wireless networking only supports a single link. It combines dual-mode hardware with multi-link data mirroring technology, greatly enhancing the system’s anti-interference capability. A typical network topology diagram is as follows:

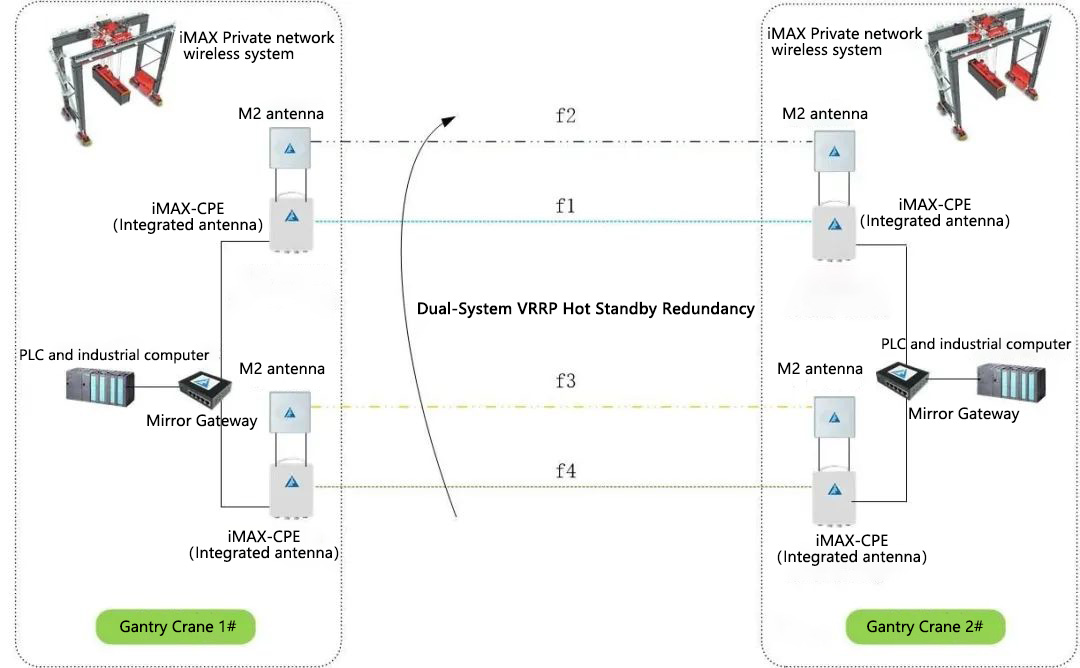

Due to the large size and high height of shipbuilding gantry cranes, the network equipment installed on them is vulnerable to damage from natural disasters such as lightning strikes. Moreover, since shipyards use industrial power supply, voltage instability and other issues are inevitable, which may cause individual failures of network equipment. This in turn can lead to the failure of the wireless system for the lifting group, affecting safe production. To maximize the reliability of the system and prevent the impact of a single equipment failure on lifting operations, GuoXin Longxin has designed a redundant hot – standby multi – link fusion solution with higher reliability. The schematic diagram of the network topology structure is as follows:

3.2 Large-Scale Intelligent Control Networking for Lifting Equipment

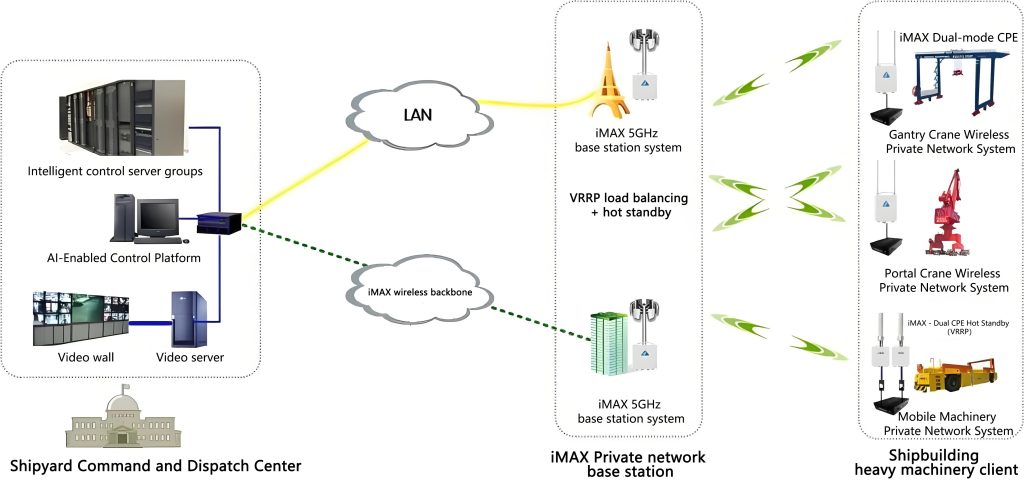

As core production equipment in shipyards, the safe operation and precise coordination of shipyard cranes are directly related to production progress and personnel safety. GuoXin Longxin’s wireless private network solution can help shipyards achieve reliable networking of numerous cranes, thereby deploying advanced crane monitoring and surveillance systems to address intelligent control systems such as anti-collision and load limiting:

- Multi-dimensional state perception network: More than 30 types of IoT terminals (such as vibration sensors, inclinometers, and current loops) are deployed on each crane. Through GuoXin Longxin’s wireless system, over 200 parameters collected by front-end sensors—including steel cable tension, track deviation, and motor temperature rise—are transmitted in real time, helping shipyards monitor the real-time status of each crane.

- Distributed anti-collision system: Based on high-precision GPS and Beidou positioning systems, UWB precise positioning (with an error of <10cm), and edge computing nodes, a direct communication channel between cranes is established. When the distance between devices enters the 50-meter warning zone, the system automatically activates hierarchical early warning (acoustic-optical alarm → speed reduction → emergency braking) with a response delay of <20ms.

- Digital twin-driven collaboration: Real-time mapping of equipment status to the digital twin platform via the iMAX private network enables dynamic optimization of the intelligent scheduling system. It realizes motor overheating risk prediction based on load current to adjust task allocation in advance, generates wire rope life curves, and accurately prompts maintenance windows.

- High-reliability private network architecture with hot standby redundancy: The iMAX wireless private network, based on technologies such as three-layer routing, Virtual Router Redundancy Protocol (VRRP), and multi-link data mirroring, adopts a high-reliability private network architecture of “multi-base station cross-coverage with hot standby redundancy and dual-mode crane clients connecting to dual base stations simultaneously”, ensuring the reliable and stable operation of the above systems.

3.3 Full-Element Interconnection of Shipyard Digital Twin

The shipyard digital twin system needs to integrate design models, production scenes and physical parameters. The GuoXin Longxin wireless private network provides a low-latency and high-performance network data channel for the digital twin system:

- 3D scene reconstruction: Laser point cloud scanners deployed at high points in the factory area are connected to iMAX private network base stations through 10-gigabit optical ports, updating the 3D model of the entire factory every 2 minutes. The network data transmission delay is less than 100ms, making real-time 3D scenes possible.

- Digital mirroring of production lines: In the pipeline welding workshop, more than 500 welding parameter sensors form an industrial Internet of Things to monitor data such as current, gas flow and weld temperature in real time, which are transmitted back to the digital twin platform through the wireless private network. The system automatically compares with process standards and gives real-time early warnings of deviations.

- Human-machine-object linkage: Operators wear smart badges (integrated with RFID and UWB). The digital twin platform can display real-time early warnings of intrusion into dangerous areas, qualification verification of special types of work, and personnel evacuation command in emergency situations, etc. These WiFi smart terminals can be connected to the network in real time through BreezeAir WiFi6 & WiFi7.

The digital twin system for shipyards is an irresistible trend in the shipbuilding industry. The iteration and evolution of the digital twin system can significantly improve the precision of hull block assembly, accelerate the response speed to design changes, and reduce the rate of quality rework. The wireless private network system of GuoXin Longxin is worthy of being the foundation of the shipyard’s digital twin system.

The intelligent remote control and unmanned driving solution for shipyard cranes is similar to those applied in scenarios such as ports and railway freight yards. Therefore, this solution will not be listed separately, and relevant technologies and cases can be referred to in the article Case Sharing on Intelligent Remote Control and Unmanned Operation of Heavy Machinery.

In addition to the above-mentioned scenarios, systems such as safety management, material management, and AI recognition and analysis in shipyards also rely on the support of wireless private networks. 4K cameras or portable mobile monitoring points based on wireless private networks, equipped with AI recognition capabilities, can detect in real time situations such as personnel not wearing safety helmets, smoke and flames in dangerous areas, and potential hazards of excessive material stacking. Alarm signals are pushed to responsible persons within milliseconds, and full-range material tracking is realized. All these help shipyards improve their management level and safety guarantee capabilities.

IV. Summary

The shipyard application scenarios covered in this solution are limited. In fact, more scenarios (such as robots, AGV and logistics transportation, intelligent control of assembly lines, etc.) also rely on the Guoxin Longxin wireless private network system, which can be referred to in Highly Reliable Wireless Private Network Solution for AGV Unmanned Driving and Wireless Communication Solution for Intelligent Robots, etc. For details on the application characteristics and scenarios of leaky wave cables, please refer to Medium and High Frequency Leaky Wave Cable Wireless Private Network Solution.

The technical discussion in this article is just a brief introduction. For details on waveguide technology and its applications, please refer to Application of Waveguide Communication in the Field of Intelligent Control of Heavy Machinery; for wireless high-reliability networking technology, please refer to How to Ensure the Reliability of Wireless Network Communication Systems?; for millimeter wave system technology and applications, please refer to Overview of Millimeter Wave Communication System Technology and Applications; and for the significance of wireless routing technology, please refer to How Important is it for Wireless Systems to Support Routing Technology?.

Guoxin Longxin has a variety of wireless technologies and can customize high-reliability networking solutions for shipyard users according to their needs. The Guoxin Longxin wireless private network networking solution has solved the problem of wireless transmission in heavy industry scenarios. Its value lies not only in technological breakthroughs, but more importantly in building a smart manufacturing base with full interconnection of equipment, full integration of data, and full interconnection of systems, providing core support for the digital transformation of the shipbuilding industry. With the in-depth advancement of the national “intelligent transformation and digital transformation” strategy, the above solutions will surely continue to empower China’s shipbuilding industry to maintain its global competitiveness.