Integrated Monitoring Solution for Oil and Gas Pipelines and Stations

I. Overview of Integrated Monitoring Requirements for Oil and Gas Pipelines and Stations

With the rapid development of China’s national economy, the issue of oil shortage has increasingly become a core aspect of China’s energy security and an important part of national security. While adhering to the principle of relying on domestic resources, China continues to implement the “going global” strategy to strengthen cooperative development of overseas oil and gas resources.

The International Energy Agency (IEA) predicted in its June *Oil Market Report* that global oil demand will grow by approximately 2.4 million barrels per day in 2023, reaching 102.3 million barrels per day, a record high. Among them, crude oil consumption in China and India will increase by 800,000 barrels per day and 300,000 barrels per day respectively.

In the first half of 2023, China’s apparent consumption of crude oil reached 386.49 million tons, a year-on-year increase of 8.9%; imported crude oil stood at 282.08 million tons, up 11.7% year-on-year, with external dependence reaching 72.8%. Apparent consumption of natural gas was 190.9 billion cubic meters, a year-on-year increase of 4.0%; imported natural gas was 78.1 billion cubic meters, up 5.8% year-on-year, with external dependence at 39.5%.

In addition, according to recent data released by the General Administration of Customs and statistical data released by the National Bureau of Statistics last year, China imported 508.28 million tons of crude oil and 109.25 million tons of natural gas in 2022, with pipeline transportation being the primary import method. Since China’s domestic oil and gas production is far from meeting domestic consumption, imports are necessary, making the safe, fast, and efficient transportation of oil and gas a key link in ensuring reliable supply.

Currently, a large amount of oil transportation is completed by sea, but this method has long cycles and high costs. Moreover, relying solely on maritime transportation is insufficient for national energy security. China’s three major oil companies and other related enterprises have invested in building a large number of oil and gas pipelines for oil and gas transmission, serving as a necessary means of importing oil and gas. Most long-distance cross-border and inter-provincial pipelines are built underground, supplemented by above-ground or overhead installations. Short-distance pipelines, such as those at oil and gas extraction sites, are generally built above-ground or overhead. To facilitate the production, processing, storage, and transportation of oil, natural gas, and chemical products, numerous above-ground oil and gas pipelines have been built in petrochemical operation areas, petrochemical terminals, oil and gas storage centers, gas companies, chemical plants, and other regions nationwide. Along with these pipelines, there are also many stations (such as pressurization stations, sub-transmission valve chambers, and distribution stations) and related equipment.

Many oil and gas pipelines are aged, and some are located in harsh environments such as high-corrosion areas. Their monitoring, management, and daily maintenance are crucial to ensuring the safety of oil and gas transportation. In particular, many gas pipelines transport gases containing hazardous substances such as hydrogen sulfide and carbon monoxide; any leakage could lead to explosions, poisoning accidents, and massive casualties. Meanwhile, criminal acts such as damaging oil and gas pipelines and “oil thieves” drilling holes in pipelines to steal oil are reported annually, causing huge economic and property losses. Therefore, it is urgent to effectively implement integrated management and control of oil and gas pipelines and stations using advanced technical means.

Guoxin Longxin has long been committed to the research, development, design, construction, maintenance, and service of networking, informatization, and automation systems in the oil and petrochemical industry. Combining years of experience in related work with oil industry enterprises, we have summarized a series of solutions for the digital construction of the oil industry, with “intelligence” at the core. Guoxin Longxin’s integrated monitoring solution for oil and gas pipelines and stations is not a simple list of multiple systems but an integrated comprehensive solution characterized by “innovation through integration and development through integration.”

II. Wireless Network Scheme Design for Integrated Monitoring of Oil and Gas Pipelines and Stations

The integrated monitoring of oil and gas pipelines and stations aims to ensure safety. From the perspective of common hazard sources, the two most frequent causes are man-made damage and aging/damage (including natural disasters), both of which must be addressed. In system construction, alarm and early warning for emergencies must be timely and reliable, while also taking into account the daily uninterrupted inspection of pipelines to replace manual work.

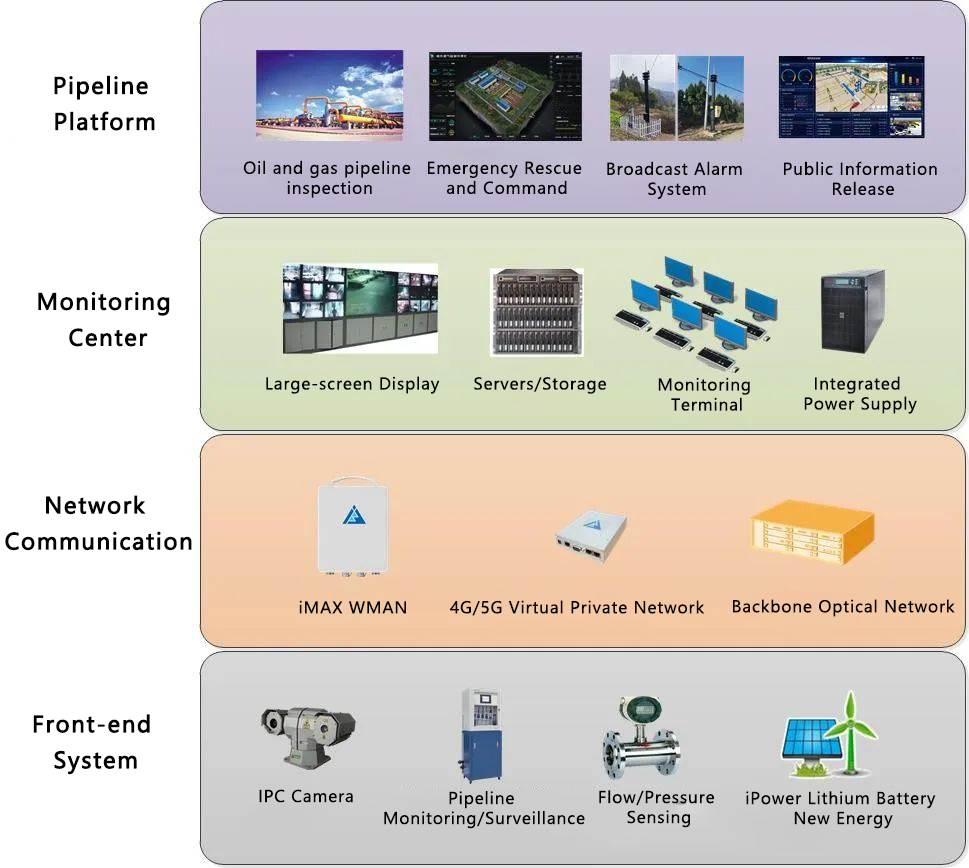

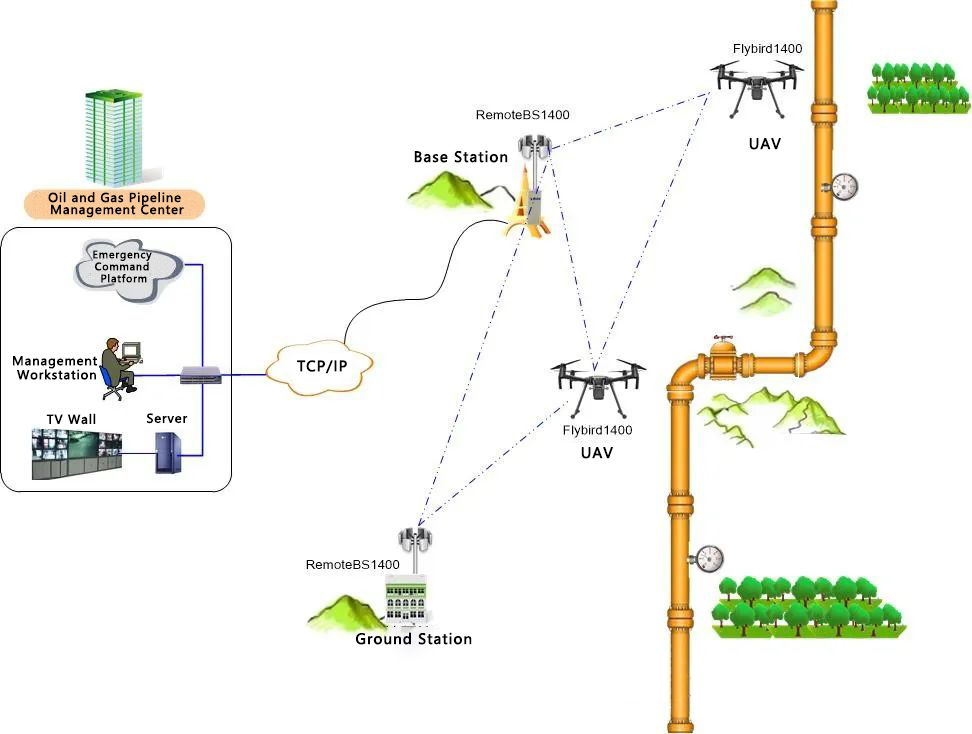

The integrated monitoring of oil and gas pipelines consists of multiple levels and numerous software and hardware subsystems, ranging from the front-end monitoring points, network communication, to the command center monitoring platform, as shown in the following figure:

The integrated monitoring and intelligent command software platform for oil and gas pipelines and stations needs to integrate GIS geographic information maps, various video surveillance systems (including infrared thermal imaging), data collected by various sensors, alarm and early warning information, etc., for intelligent analysis and calculation. It also needs to have remote command and resource scheduling capabilities. Therefore, the software platform must be a customized development system based on the actual needs of specific users, which will not be elaborated on in this plan.

Since pipelines are deployed in two ways: buried and above-ground, our solutions will also be designed specifically for these two ways.

1. Monitoring of above-ground and overhead pipelines

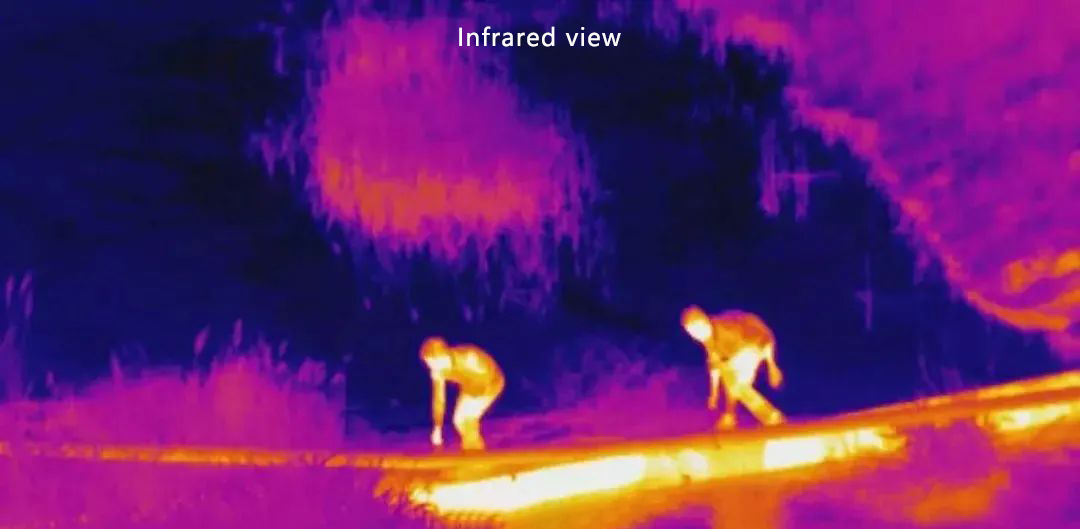

The comprehensive monitoring of above-ground and overhead pipelines is relatively easy. At present, mature dual-spectrum imaging technology can meet the monitoring needs for man-made damage and aging damage. The so-called dual-spectrum surveillance camera is an integrated monitoring system that integrates a high-definition network camera and an infrared thermal imaging camera.

Among them, the network camera (IPC) mainly realizes high-definition digital video monitoring during the day through visible light. Through real-time streaming images and intelligent video analysis and calculation of the back-end platform, it monitors possible man-made damage and pipeline leakage, and automatically issues alarm information for staff to handle in a timely manner.

Infrared thermal imaging lenses mainly form images by receiving infrared rays emitted by different objects. The technology of mid-to-high-end infrared thermal imaging systems originates from military industry, which can realize temperature sensing of objects within a few kilometers. Through temperature difference sensing, it can identify pipeline damage, gas leakage, oil leakage and the movements of surrounding personnel, etc. Combined with the intelligent analysis and calculation of the back-end platform, it can meet the needs of day and night monitoring of pipelines. Especially at night, infrared thermal imaging technology is more reliable than visible light monitoring.

In addition to optical monitoring methods, appropriate intelligent control sensors and instruments can also be considered along the pipeline to measure parameters such as pipeline pressure, further ensuring the reliability of the system.

Due to the special geographical environment of the power supply for the above-mentioned monitoring points—most of which are in remote and sparsely populated areas—the most suitable solution is to adopt the lithium battery solar power supply system iPower2000. Guoxin Longxin iPower2000 is an off-grid independent solar power supply system based on lithium batteries and high-performance monocrystalline silicon solar panels. Compared with ordinary solar power supply systems using lead-acid or gel batteries, it has advantages such as a simple structure, small size, light weight, and a large number of charge-discharge cycles, making it an ideal choice for IT system construction in field environments.

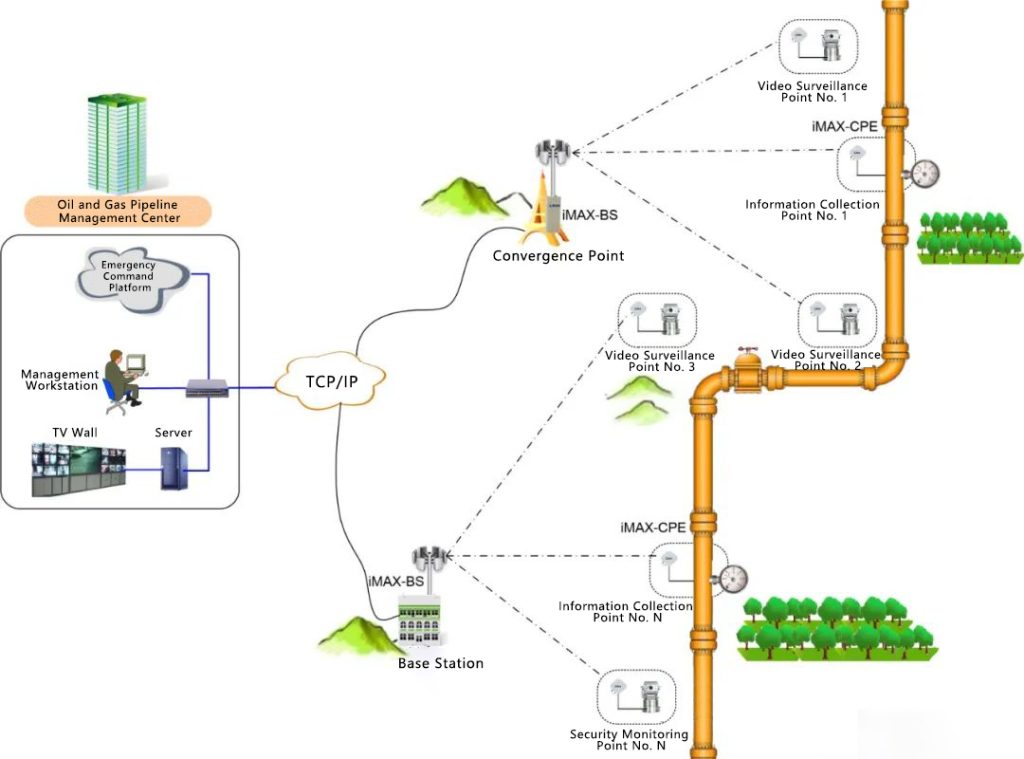

For the networking of monitoring points, a reliable, high-capacity, and long-distance dedicated network should be used. However, wiring around pipelines that cross high mountains, steep ridges, rivers, and lakes is very inconvenient. Therefore, wireless metropolitan area network (WMAN) technology is the best choice, and the 5G iMAX wireless private network system is the most ideal solution. This system features an extremely long communication distance, high reliability, strong confidentiality, and multi-purpose use of the private network, making it the first choice for building field private networks.

Guoxin Longxin iMAX Wireless Metropolitan Area Network (WMAN) Private Network System is specially designed for constructing outdoor ultra-long-distance and large-capacity private network systems. With its unique technical advantages and outstanding performance—such as supporting multiple networking modes, meeting the IP67 protection standard, and having large-capacity high-definition video bearing capacity—it also boasts advantages that other wireless broadband devices cannot match, including ultra-long-distance networking, high bandwidth, strong anti-interference ability, high reliability, easy installation, and convenient maintenance. The iMAX wireless communication system has high bandwidth and multi-service hybrid networking capabilities, and fully adopts TCP/IP protocol standards. It is very suitable for transmitting “multi-network integration” of multiple media types (including video, voice, network, and data) in power online monitoring systems and video surveillance management, ensuring the application effect of multiple systems.

It should be emphasized that the video intelligent analysis platform deployed in the command and monitoring center is crucial for the operation of this system, and it must be developed and deployed in a customized manner according to the user’s on-site conditions to ensure that the system’s alarms are timely and effective.

The topology diagram of the integrated monitoring system for above-ground and overhead pipelines is as follows:

2. Comprehensive Monitoring of Buried Pipelines

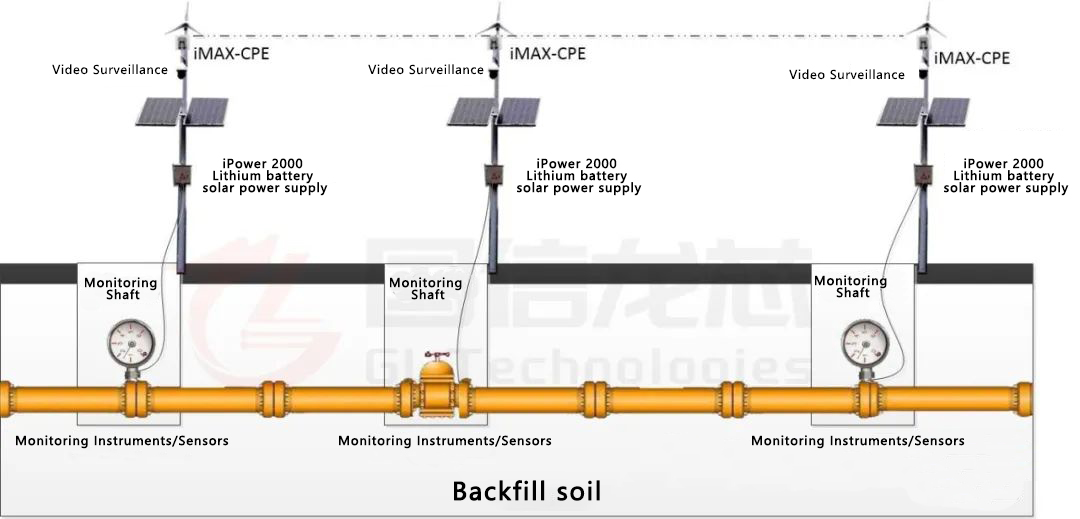

The construction of comprehensive monitoring for buried pipelines is more challenging. In addition to deploying pressure monitoring and other measurements at booster stations and monitoring stations, a better monitoring method is to construct monitoring shafts at certain intervals along the pipeline, which are specifically used for real-time pipeline monitoring and fault maintenance. The pipeline inside the shaft is exposed, and sensors for pressure, temperature, etc., can be installed on it. The power supply is provided by the iPower2000 lithium battery wind-solar hybrid power supply system mounted on the pole outside the shaft. To ensure the safety of the shaft and related equipment and replace manual real-time inspections, video surveillance cameras are installed on the pole. Networking is achieved through the iMAX wireless metropolitan area network system to build a private network, enabling interconnection with the command center.

The topology diagram of the comprehensive monitoring system for buried pipelines is as follows:

Although this solution is more difficult to implement and costly, it can localize the leakage problem to specific sections, greatly reducing the difficulty of location and maintenance and shortening the fault handling time. It is a relatively feasible solution under current buried conditions.

Compared with pipeline monitoring, the comprehensive monitoring of stations (unmanned or manned) is relatively easier, and even national standards have been established during the early planning stage of construction. However, in actual use, monitoring and alarm schemes that solely rely on gas sensors or other single means are unreliable. Frequent missed alarms or false alarms significantly reduce the practicality of the system. Compared with the aforementioned pipeline monitoring schemes, adding an infrared night vision inspection and intelligent analysis system will greatly improve the reliability of leakage early warning and ensure the safe operation of stations.

In addition to the above conventional comprehensive pipeline monitoring methods, the following two supplementary systems can also be expanded:

1. Infrared night vision UAV patrol inspection

At present, the development of camera-equipped UAVs is very rapid and increasingly mature. Using a four-rotor UAV equipped with an infrared night vision camera suspension system can realize day and night patrol inspection of pipelines.

UAVs can be carried on dedicated patrol vehicles to complete aerial inspections of a section of area at one time and detect potential safety hazards in a timely manner. For communication between UAVs and patrol vehicles, the Huanyou low-frequency MESH mobile communication system can be selected. If an iMAX wireless metropolitan area network system has been built along the pipeline and connected to the monitoring and command center, within the effective coverage area of iMAX base stations, patrol vehicles can also connect to the network in real time, enabling the back-end command center to retrieve UAV images in real time.

2. Portable monitoring points for emergency monitoring

For emergencies or emergency pipeline repairs, portable monitoring point systems or detachable monitoring point systems can be deployed as needed for rapid, temporary, and emergency monitoring. The iMAX wireless metropolitan area network system can transmit real-time high-definition images from the scene back, and the monitoring and command center can issue disposal orders remotely to guide on-site repair work.

The Guoxin Loongson iCMVS detachable monitoring point system consists of an IP HD video surveillance camera, iMAX wireless metropolitan area network terminal, high-performance UPS power supply, supporting tripod, and other components. Despite its complexity, it can be simply packed into boxes, is easy to install, and can be disassembled and relocated at any time. Through integrated professional design, the system can meet the working requirements of outdoor environments (such as rain resistance, high and low temperature resistance, etc.), while solving the problems of HD video surveillance, power supply, and IP network connectivity. It is an ideal choice for temporarily and emergently setting up video monitoring points. The above solutions integrate products and technologies from multiple manufacturers, requiring collaborative integrated design from all parties. In fact, as long as the wireless private network along the pipeline is built, it will serve as the neural network of the oil pipeline. The IT or intelligent applications that can be implemented are far more than the basic systems mentioned in the above solutions. They can be expanded to include such systems as alarm horn broadcasting systems, emergency command and management systems, disaster early warning and management systems, etc. Guoxin Loongson can provide users with targeted wireless solution designs.