Typical application scenarios of overhead cranes are illustrated as follows:

- Metallurgy: Iron and steel plants, electrolytic aluminum plants, rare earth smelters, electrolytic copper plants, etc.

- Factories: Cement plants, machinery manufacturing plants, automobile factories, maintenance plants, etc.

- Environmental Protection: Sewage treatment plants, waste incineration plants, etc.

- Energy: Hydropower stations, thermal power plants, etc.

As large-scale mechanical equipment, overhead crane operations inherently carry certain risks. To ensure their stable and safe operation, crane monitoring and management systems (CMS), anti-collision systems, and even digital twin systems are required, all of which rely on a reliable, secure, and stable network.

Meanwhile, due to the harsh working environment, monotonous nature of the work, growing difficulty in recruiting crane operators, a marked increase in human resource costs, and rising management challenges with the younger generation, intelligent AI automation, remote control, and even unmanned operation of overhead cranes have become an inevitable choice for industry development. Remote control and unmanned operation impose higher requirements on the network compared to monitoring systems, demanding latency of less than 20 milliseconds and a packet loss rate infinitely close to 0.

Most overhead cranes are mobile. Traditionally, drag chain and cable trolley systems were used to meet their communication needs. However, due to high costs, poor reliability, short service life, and difficult maintenance, wireless communication technology has emerged as the most suitable solution for overhead crane networking.

Wireless systems are the optimal choice for intelligent control or autonomous operation of overhead cranes, but not all wireless systems can meet the networking requirements of crane intelligent control. They must satisfy the following key criteria:

1.Security, Security, and Security: The security of the communication system is one of the fundamental guarantees for the safety of remote-controlled or autonomous overhead crane operations. Therefore, wireless products using carrier 5G networks connected to the Internet or open IEEE 802.11a/b/g/n/AC WiFi protocols can hardly meet security requirements. For secure network design, please refer to the article Network Security Is Not to Be Taken Lightly—You Can’t Afford the Consequences!.

Only wireless private network systems that adopt proprietary communication technology for “exclusive private network use” and support wireless packetization, channel encryption, access control lists (ACL), virtual local area networks (VLAN), virtual private networks (VPN), and even firewall technology can ensure network security. A multi-dimensional, comprehensive security architecture is one of the core advantages of Guoxin Longxin’s iMAX Wireless Metropolitan Area Network.

2.High Bandwidth: Wireless bandwidth is the basic capability to support the communication of business systems. Remote control and intelligent systems involve the transmission of large volumes of data, video, and voice, usually requiring high bandwidth ranging from tens to hundreds of megabits per second to meet operational needs. The bandwidth performance of Guoxin Longxin’s iMAX Wireless Metropolitan Area Network system is consistent with its model specifications, with no false advertising. Tailor-made solutions fully guarantee the bandwidth requirements of crane networking.

3.High Capacity: All wireless communication systems have the concept of “capacity”. The “capacity” of the iMAX wireless system refers to two aspects: first, the number of concurrent user-side CPEs connected to a base station (BS); second, the total capacity of IP HD video supported by the system. The high capacity of Guoxin Longxin’s products relies not only on hardware architecture but also on extensive optimizations in software architecture. By adopting proprietary iMAX-wireless communication technology, the system capacity is significantly enhanced.

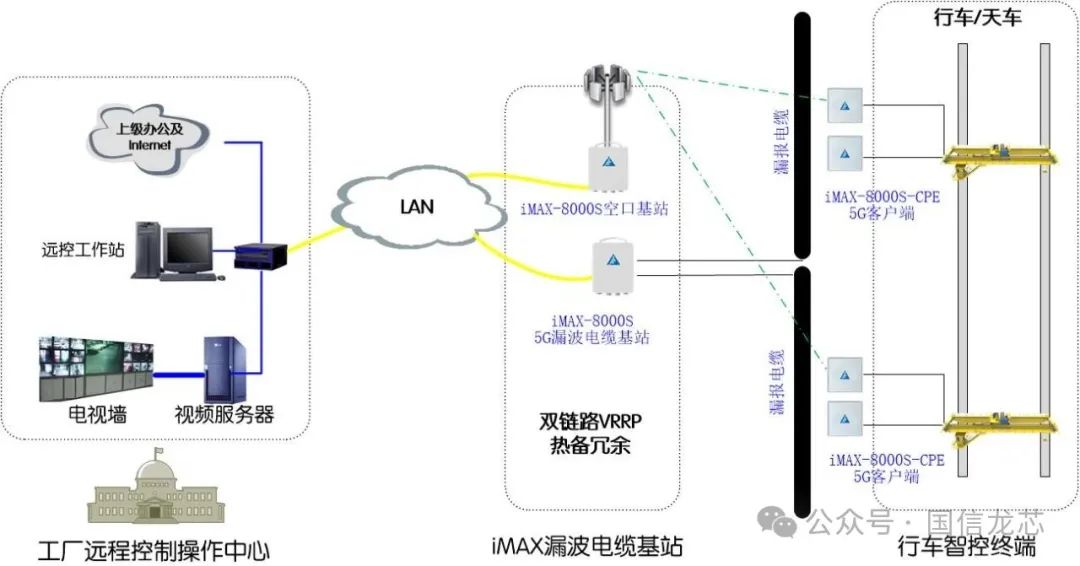

4.Reliability: The quality of Guoxin Longxin’s iMAX Wireless Metropolitan Area Network system has an excellent reputation in the industry, with numerous cases of continuous stable operation for years in harsh environments—our products are our best market advocates. In addition to equipment quality, ring network and redundant hot standby design in the solution architecture are also essential factors for reliability. The iMAX Wireless Metropolitan Area Network system supports multiple redundancy technologies such as RSTP, VRRP, and ring network routing. In particular, VRRP virtual router hot standby technology and multi-link data mirroring technology can fully guarantee link reliability.

For the design principles of wireless system reliability, please refer to the article How to Ensure the Reliability of Wireless Network Communication Systems?.

5.Anti-Interference Capability: Interference is an unavoidable issue when using wireless systems. A notable advantage of the iMAX Wireless Metropolitan Area Network system over general-purpose WiFi bridges is its enhanced anti-interference capability.

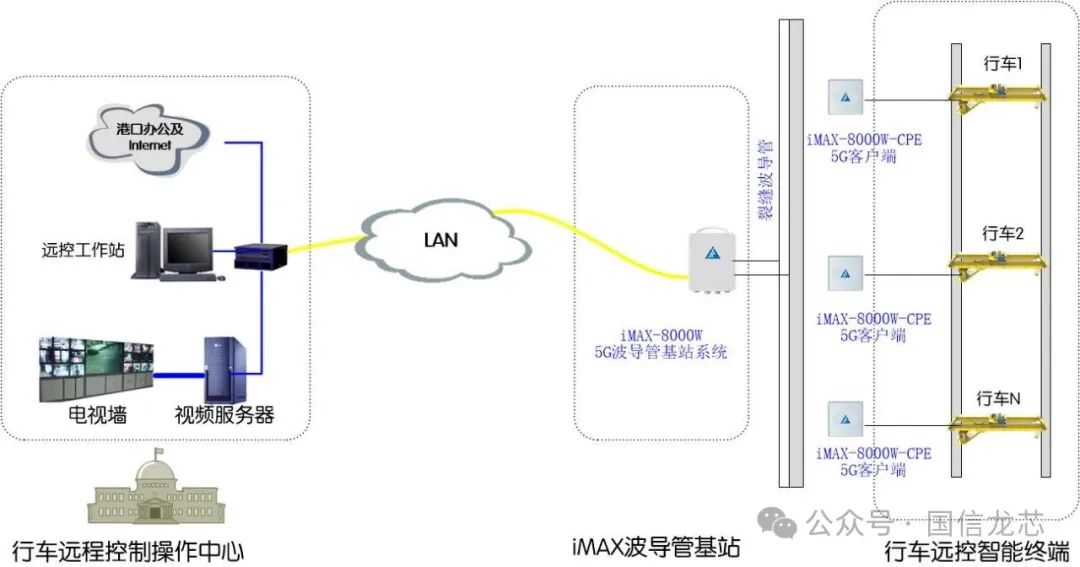

For crane networking in scenarios with complex electromagnetic environments (e.g., electrolytic aluminum plants, hydropower stations, electromagnetic cranes, metal processing factories), slotted waveguide or medium-high frequency leaky cable solutions can be adopted to significantly improve the anti-interference capability of the crane networking system, ensuring that network latency, packet loss rate, and bandwidth stability meet the real-time and transmission stability requirements of intelligent control.

6.Roaming Mobility: Remote control or unmanned operation scenarios of overhead cranes all involve mobile networking. The low latency, mobility support, and seamless roaming between base stations of the iMAX Wireless Metropolitan Area Network system are all addressed through system architecture and technical optimization, making these technologies highly suitable for the stable and reliable networking of mobile overhead cranes.

7.Environmental Adaptability: The iMAX Wireless Metropolitan Area Network system includes indoor and outdoor equipment models. Outdoor ODU devices offer outstanding environmental adaptability with waterproof, lightning protection, dustproof, corrosion resistance, and wide temperature range capabilities, ensuring stable operation in various harsh working environments. Even indoor devices comply with industrial-grade high-reliability standards in terms of dustproofing and wide temperature tolerance.

8.Network Features: One of the key differences between the iMAX Wireless Metropolitan Area Network system and wireless bridges is that it supports not only transparent bridging protocols but also routing protocols (static routing, RIP, OSPF, BGP, etc.), which is crucial for large-scale network deployment. Additionally, it supports firewall functionality comparable to professional firewall devices, bringing convenience and efficiency to user network security and networking.

Support for routing enables the construction of backbone routing ring networks, centralized management and control of all overhead cranes in a plant, isolation and interconnection of different services (e.g., video and control), and design of redundant links to improve system reliability. For large and medium-sized enterprises with centralized intelligent control projects for multiple overhead cranes, the application of routing technology is critical. Please refer to the article How Important Is Routing Technology Support in Wireless Systems?.

Guoxin Longxin’s iMAX Wireless Metropolitan Area Network system not only supports routing but also VRRP virtual router hot standby technology, achieving a “no primary-secondary distinction, mutual hot standby” link backup effect. VRRP technology enables full utilization of bandwidth resources, ensures ultra-fast and “seamless” switching of hot standby links, and automatically restores the initial state after link recovery, making it an ideal hot standby technology (for technical details, refer to the article Application of VRRP Technology in iMAX Wireless Private Network Networking). The iMAX Wireless Private Network system also features unique technologies such as Multi-link Data Mirroring (MLDM) and threshold-based network switching, which are indispensable for remote control and intelligent projects in various industries.

Common wireless technologies for overhead crane networking include WiFi, 4G/5G, and wireless private networks. Which one is most suitable for crane intelligent control networking that requires both low cost and high reliability?

If WiFi technology is used for crane networking, its limitations include insufficient service-bearing capacity, generally poor anti-interference capability, and unstable bandwidth with large fluctuations. Especially in scenarios requiring HD video transmission, WiFi cannot guarantee system stability and reliability, with video freezes and mosaics being common issues.

In addition, can carrier 4G/5G meet the communication needs of overhead cranes? Crane communication has stringent requirements for security and reliability. Except for scenarios where 5G must be used, “public network technologies” such as 4G/5G that connect to the Internet are generally not adopted, as they cannot guarantee security, reliability, or capacity. Moreover, the traffic-based billing method results in prohibitively high usage costs that users cannot afford.

Therefore, the preferred networking solution for overhead cranes is the “private network” implemented through “physical isolation”, among which Wireless Metropolitan Area Network (WMAN) private network technology (e.g., iMAX Wireless Metropolitan Area Network technology) has the best application prospects.

Guoxin Longxin is one of the earliest wireless vendors to enter the field of intelligent unmanned driving and remote control of large overhead cranes, with typical cases covering numerous industries across the country. This solution aims to summarize the wireless communication technologies and application characteristics required for crane intelligence. Since the intelligent networking requirements of overhead cranes vary across different industries and scenarios, further demand analysis and solution design are provided below.

Based on years of experience in designing and implementing automation and intelligent control solutions for overhead cranes, Guoxin Longxin has summarized several commonalities of crane communication networking:

1.Exclusive Private Network Use Is the Preferred Solution:

Crane communication is usually confined to a single track or a specific area. Should a private network (or dedicated network system) or a public network (generally referring to carrier-operated networks) be used? A consensus has been reached in recent years: only private network technology with exclusive private network use can meet the requirements for network reliability, security, and stability in crane intelligent control.

Adopting a private network (self-built network), including Wireless Local Area Network (WLAN) or Wireless Metropolitan Area Network (WMAN) private networks, offers obvious advantages: security, reliability, consistent performance as designed, no long-term costs such as traffic fees or link rental fees, and good economic efficiency.

Adopting public network technologies (e.g., carrier 4G/5G) has the advantage of eliminating the need for self-built base stations—network access can be achieved by adding a 4G/5G terminal as long as signal coverage is available. However, its drawbacks are also prominent: insecurity, poor reliability, and instability. After all, such connections rely on carrier network platforms; once the number of users surges, the network becomes unusable. Additionally, connecting to public cloud platforms via the Internet exposes the system to constant security threats such as hacker attacks and data hijacking. If a crane system with high-capacity video transmission accesses the network through a single base station, it may even overload the carrier’s base station, leading to serious usability issues. Furthermore, regarding traffic costs, video surveillance applications calculated on a traffic-based billing model result in “astronomical figures” that most users cannot afford. For more details, refer to the documents Network Security Is Not to Be Taken Lightly—You Can’t Afford the Consequences! and What Is a 5G Private Network?.

Therefore, the optimal communication solution for overhead cranes is still a private network, i.e., a “wireless private network”. Only exclusive private network use can ensure the reliability, security, and stability of the system.

2.High Reliability and High Availability:

The wireless communication networking system for overhead cranes must ensure reliability when in operation. Since it involves crane control, it is closely related to operational safety, making civilian-grade WiFi networking or 4G/5G solutions unsuitable. Therefore, tailored customization in technical solutions, equipment selection, antenna configuration, and installation processes is essential to ensure high availability and reliability.

For crane applications in scenarios with severe electromagnetic interference, such as electrolytic aluminum plants, hydropower stations, electromagnetic cranes, and metal processing factories—especially projects involving remote control and unmanned operation—pure wireless air interface solutions can hardly guarantee that network packet loss rate, latency, and bandwidth stability meet the real-time and transmission stability requirements of intelligent control. Therefore, special technologies are required to address these challenges, such as slotted waveguide systems or medium-high frequency leaky cable systems.

For slotted waveguide technology, refer to the article A Brief Analysis of Slotted Waveguide Communication Technology and Its Applications; medium-high frequency leaky cable systems can be regarded as a low-cost alternative to slotted waveguide technology, as detailed in the document Medium-High Frequency Leaky Cable Wireless Private Network Solution.

3.Integrated Multi-Service Bearing:

The wireless communication networking system for overhead cranes must have sufficient bandwidth, support real-time two-way communication, and be capable of carrying services such as HD video, 3D spatial scanners, trolley/hoist operation data, sensor data, and other crane-related data. It must comply with TCP/IP standards to facilitate system expansion for more functions and meet further intelligent requirements.

For multi-service hybrid networking, in addition to fully meeting bandwidth requirements, service planning and isolation (e.g., separating video and control services) are necessary to avoid system anomalies caused by IP and network conflicts between systems from different vendors. This requires software firewall technology to ensure security. Refer to the article Introduction to Firewall Technology in iMAX Wireless Systems.

4.User-Friendly Operation:

Guoxin Longxin has always strived to turn complex technical solutions into “user-friendly applications” for end-users. This ability to simplify complexity is based first on accurate understanding of user needs and second on continuous research and exploration of various technologies.

In summary, the networking solution for the intelligent system of overhead cranes must be customized according to the specific actual needs of each user.

Taking overhead cranes as an example, the following are application solutions for crane networking in typical scenarios:

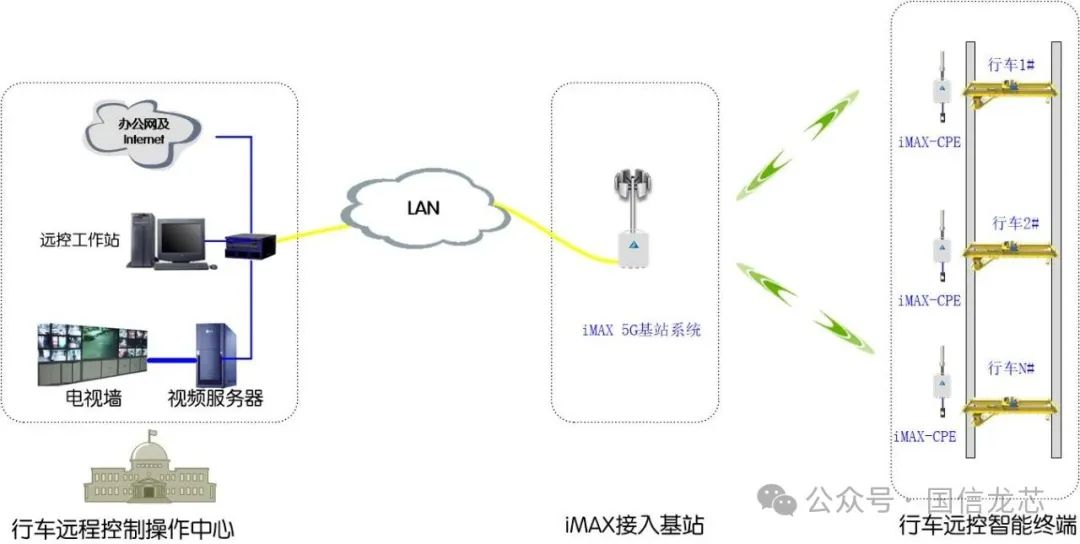

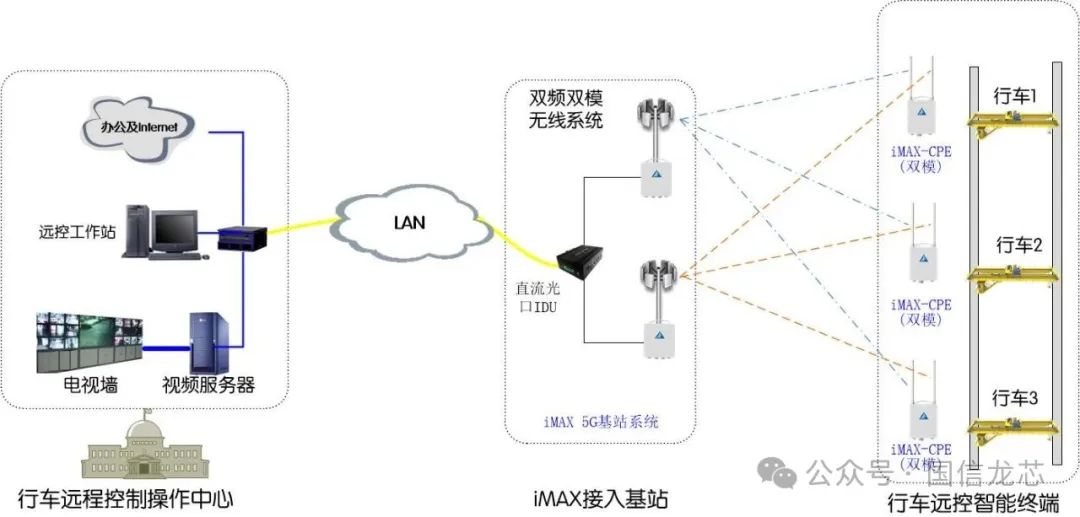

1.Pure Wireless Air Interface Overhead Crane Networking Solution

The application requirements of overhead crane wireless communication networking systems vary across industries, and thus their system configurations also differ. Taking the wireless communication networking system of overhead cranes in common manufacturing plants as an example, the system topology is illustrated below (1 set of base stations (BS) to enable networking between multiple overhead cranes and the ground control center):